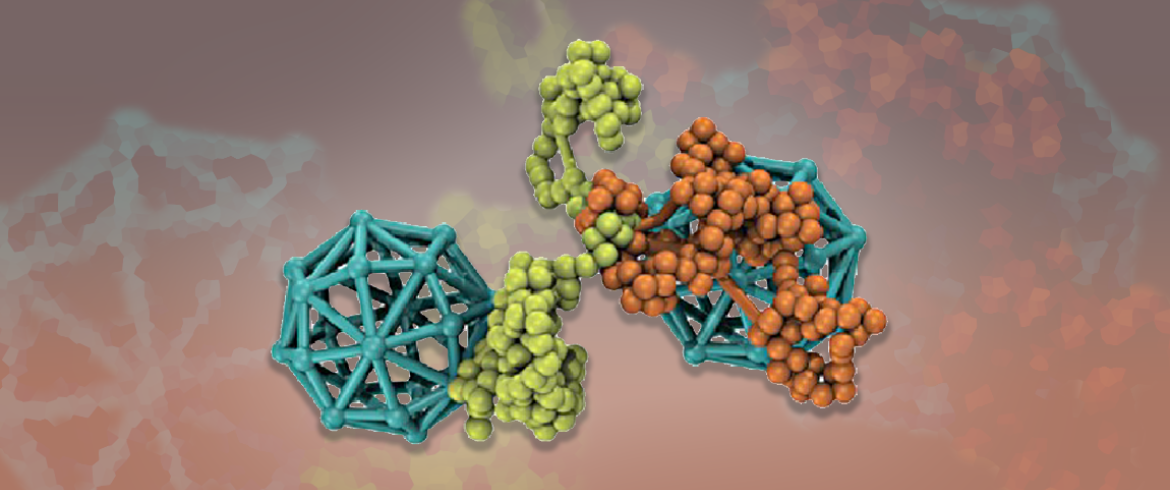

Understanding the key combinations of polymers, their chain properties and particle size could be key to developing the high-performance polymers of the future. A key study in Associate Professor Daniel Hallinan’s lab at the FAMU-FSU College of Engineering may hold the secret. (Photo illustration by L. Hall)

Polymer-grafted nanoparticles look like long chains of spaghetti, with ball-like attachments at the ends. These strange shapes have the potential to improve the design of high-performance materials. Polymer-grafted nanoparticles are the hope for next-generation materials used for everything from electrical energy storage to space travel. The U.S. Air Force has taken notice.

A team of researchers from the FAMU-FSU College of Engineering and Ohio State University is investigating the flow properties of these polymers with a $790,000 grant from the Air Force Office of Scientific Research (AFOSR), through Florida A&M University.

“The Air Force needs very light, very strong materials that are resistant to high temperature,” Daniel Hallinan, an associate professor from the FAMU-FSU College of Engineering Department of Chemical and Biomedical Engineering, said. “Pre-ceramic composites are commonly used for those applications but there are issues during the design process that we want to improve.”

In recent years pre-ceramics have been used in complicated structures as part of high-performance parts. Because they can be shaped and poured into complex molds for use in extreme environments such as heat shield materials, pre-ceramics are highly desired. However, when heated to high-temperatures and then cooled, they shrink— a lot.

“We want to reduce the volume shrinkage that occurs during the processing,” Hallinan said. “Polymer-grafted nanoparticles have the properties we need for high-performance and we want to improve the way these materials flow to optimize the process.”

Subramanian Ramakrishnan, a professor in the same department at the joint college and an expert in nanoparticles and colloids, and Lisa Hall, a chemical engineer from Ohio State University who specializes in simulations on the project, are working with Hallinan on the project.

Together they are studying thin layers of polymer-grafted nanoparticles because they are the size of the systems the simulations can work with. Simulations require lots of calculations and have limitations on how long they can feasibly run.

“When Dr. Hall recreates the materials we are making in the lab in a computer, she sees some things we can’t see, because experiments just can’t do everything,” Hallinan said. “We want to have direct comparison to measures we make on real materials and the results from the simulations.”

A problem that affects a material’s ability to flow is something the researchers call entanglements. The spaghetti-like chains can knot or twist when attached to different particles. The team is looking at polymer links, particle size, and several independent variables to see how the parameters affect the structure and flow ability.

The combination of looking at the flow properties in experiments and simulations is a novel approach that hasn’t been done before.

“We expect our discoveries will provide new knowledge in the design of materials,” Hallinan said. “A key outcome is being able to tell the Air Force that if they want a particular material to flow properly, they should, ‘link X polymer, and have X chains per particle, with X size particle.’ In the end it’s about better measures to process successfully.”

As with all research at a teaching university, infusing projects with student education is a key goal. According to Ramakrishnan, this grant offers new opportunity for students to work on research for the Air Force Research Labs, with some of the leading scientists in the country. Additionally, the graduate students on the research team will train in the specialty area of high-performance materials.

“This project will prove to be a valuable experience for both students and faculty and will open up a number of future opportunities,” he said.

RELATED ARTICLES

Engineering professor collaborates with researchers on artificial muscles

Researchers develop battery component that uses compound from plants