TECT Power

Turbine Engine Component TechnologyTECT Power manufactures critical rotating components and assemblies for turbine engines for aviation and industrial applications, as well as components for other industries with similar engineering and quality requirements. Our five facilities are spread throughout the U.S. and feature a broad range of manufacturing technology and capabilities.

These technical abilities are just one of the reasons TECT Power is an industry leader in the forging and complex 5-axis milling of turbine engine components for aerospace gas turbines, industrial gas turbines and steam turbines. In addition to being a one-stop shop, TECT Power is a business unit of TECT and is supported by Stony Point Group.

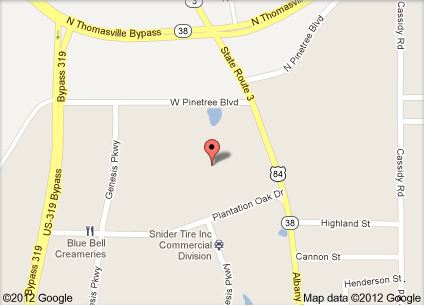

Location

Thomasville, GAApproximately 50 minutes from COE

1211 Old Albany Road

Thomasville, GA 31792-3552

Phone: (229) 228-2600

Thomasville, GA 31792-3552

Phone: (229) 228-2600