Application of Unsteady State Heat Transfer in Industry

An example of the unsteady

behavior of such a system is the thermal spray process commonly used in coating

industry. Fine solid particles are

injected into a stream of high temperature gas flow.

The particles are soften or melt before they strike onto the processed

surface, providing a layer of uniform coating for protection, wear-resistance or

as thermal barrier. The process is

very complicated involving high temperature, physics, fluid mechanics, material

characterization, and unsteady heat transfer.

The following is a short introduction of a thermal spray process.

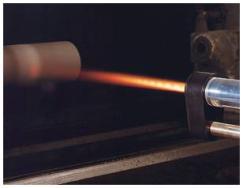

High

Velocity Oxygen Fuel (HVOF) process involves the use of exhausted flame gas from

a combustor to accelerate the injected coating particles to very high velocity

(can be exceeding 1500 m/s well into the supersonic range).

The high energy impact of the high velocity particles will be enough to

coat the material onto the surface and the completely melting (phase transition)

of the particles is not required. Therefore,

it usually can provide a thicker and more uniform coating compared to other

thermal process. As ahown in the

following figure, periodic structures (usually be called as shock-cells) exist

inside high speed jet, as also evident from the picture following the schematic.

HVOF

System from Metal Spray Supply, Inc.

Coating

Process

http://www.eng.fsu.edu/~shih/succeed-2000/roadmap/map.htm

What

is Unsteady State Heat Transfer |

Unsteady State Heat

Transfer Experiment |

Examples of Unsteady State Heat Transfer | |

Applications

in Industry

| Definitions

| References